Water Content in Construction Timber

In the realm of construction, where precision and longevity are paramount, one often overlooked yet vital factor is the moisture content of timber. The presence of water in construction timber, when a building is enclosed, can have far-reaching consequences, affecting structural integrity, aesthetics, and even health.

Before we dive into the complexities, it's crucial to understand why water content in construction timber is important. Timber is a hygroscopic building material, cherished for its versatility, sustainability, and aesthetic appeal. But timber and timber-based materials can be degraded or altered by organisms, affecting their quality. The mere presence of organisms on timber or timber-based materials does not necessarily lead to damage to an extent that poses a risk of structural issues.

Timber - decaying fungi can develop when local timber moisture is approximately at fiber saturation. Insects can develop at lower moisture levels, but are usually eliminated during the technical drying process during manufacturing.

Elevated moisture levels can lead to a litany of problems, including warping, decay, and compromised structural integrity. Hence, the moisture content of timber during construction is a critical factor that demands careful consideration.

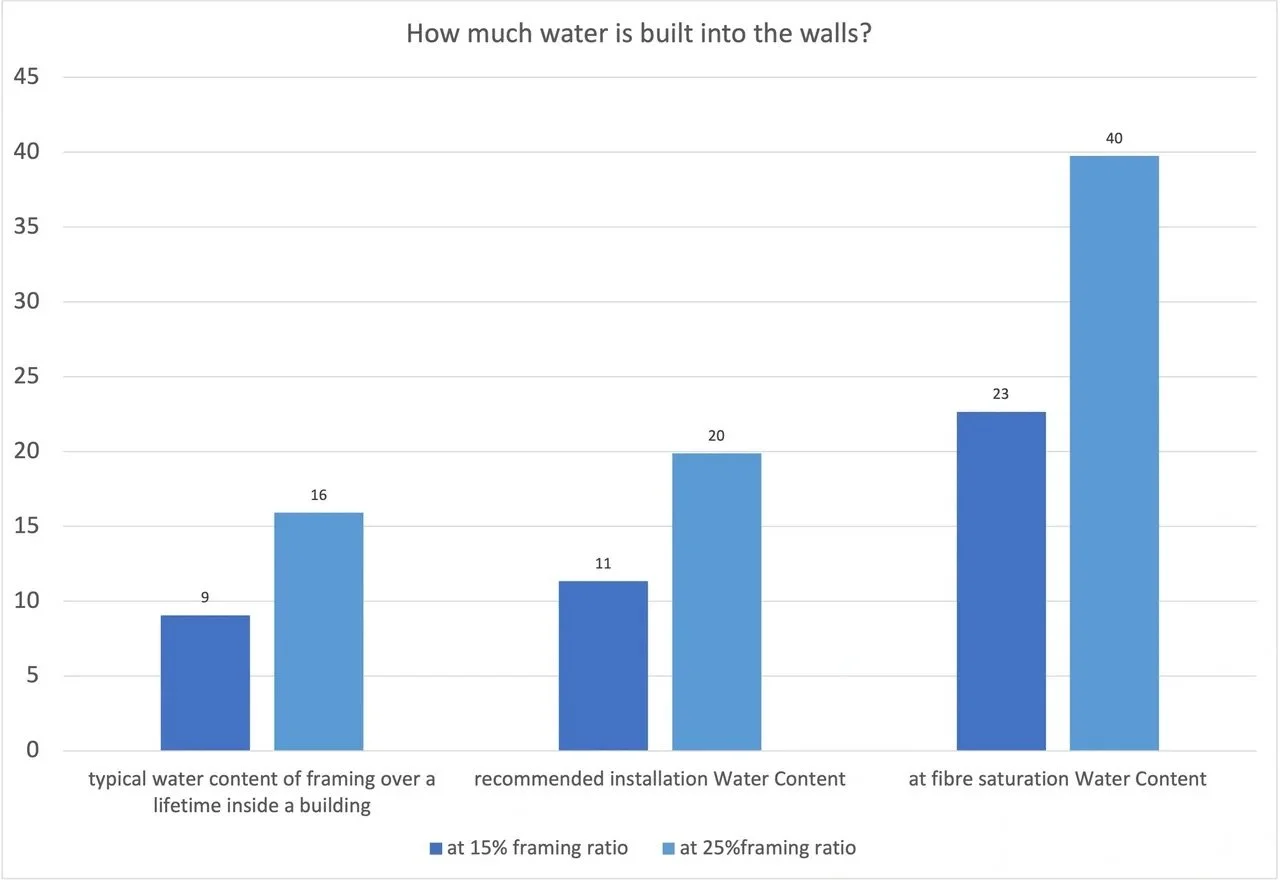

We have looked at 3 different levels of moisture content important during construction process:

equilibrium water content (the water content that the timber will adapt to once it is in its in-use state)

recommended enclosure water content (the recommended maximum before the building is enclosed)

fibre saturation (the maximum capacity that timber can absorb water)

These parameters vary depending on factors such as climate, framing percentages, and timber species. For this study we used the average density between fir, spruce and pine (≈500kg/m3) and an average fibre saturation percentage of 30%; some species can absorb up to 34%.

In New Zealand, construction timber typically leaves factories with a moisture content of around 20%, or lower. It is recommended to enclose timber below this threshold. However, in practice, timber structures also often remain exposed to the elements for extended periods, leading to moisture absorption well beyond the desired levels. This discrepancy between recommended and actual moisture content can have significant repercussions.

numbers represent litres of water per m2 of wall area

The difference in litres per m2 for extensive framing left out in the weather is significant with up to 20l/m2 extra water!

The consequences of high moisture content in enclosed timber are manifold. Perhaps the most visible issue is the growth of mold and decay. These not only compromise the structural integrity of the timber but also pose health risks to occupants. Furthermore, elevated moisture levels can mimic internal condensation issues, leading to misdiagnoses and potentially costly remedies. Neglecting moisture control can have financial and structural implications that extend far beyond the construction phase.

To mitigate these challenges, it is imperative to employ effective strategies for managing timber moisture content. Proper storage, ventilation, and vigilant monitoring are essential. Ensuring timber is adequately protected from the elements during construction and employing moisture meters to track moisture levels can go a long way in maintaining optimal conditions.