All Vapour Barriers Are Vapour Control Layers, But Not All Vapour Control Layers Are Vapour Barriers – Here's Why It Matters

Let's talk about a term that's thrown around a little too loosely in the construction and building materials industry: "Vapour Barrier." Whether you're an architect, contractor, or building consultant, you've probably heard this term used to describe a wide range of materials designed to manage moisture in buildings. But here's the thing – not all materials labeled as vapour barriers are created equal, and using the wrong one in the wrong place can lead to major headaches down the line.

Moisture issues in buildings are a serious concern. From mould growth and structural damage to poor indoor air quality, the consequences of improper vapour control can be costly and harmful. Many professionals, despite their expertise, still default to using the term "vapour barrier" for all moisture control membranes, often overlooking the nuances of vapour permeance and resistance. This broad-stroke approach can result in unintended moisture accumulation, leading to mould, rot, and ultimately, expensive remediation.

Vapour control layers should specifically refer to layers and membranes that are designed to control vapour movement. It's important to note that every building material has a vapour permeability that falls somewhere on the scale from being highly permeable to impermeable. This includes common materials such as plasterboards, plywood, and concrete. However, specialised membranes, such as smart or intelligent vapour control layers like Proclima Intello and similar products, are designed to adapt their permeability based on environmental conditions, offering more advanced moisture management solutions.

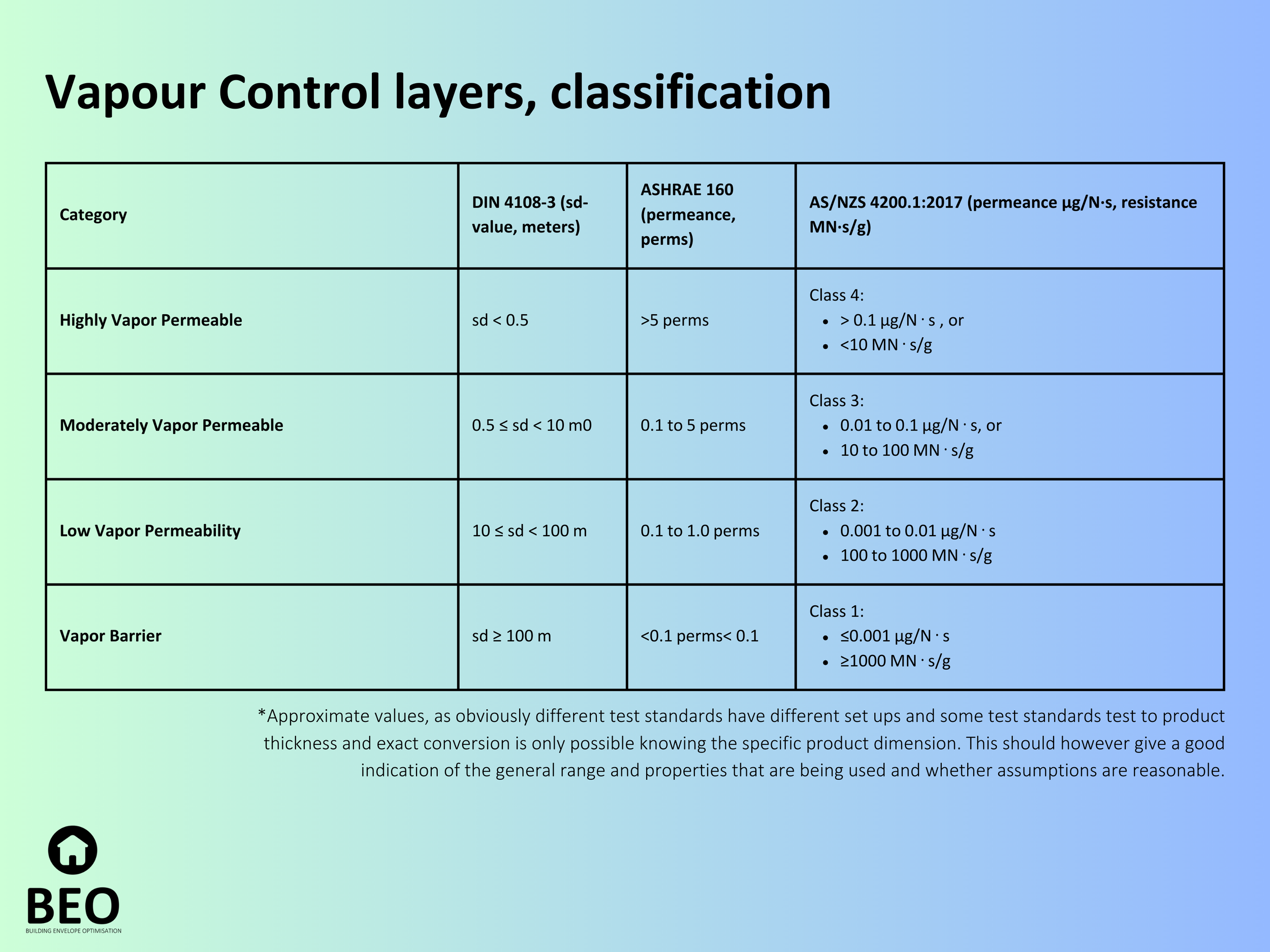

So, what’s the solution? The key lies in understanding and adopting the correct terminology: "Vapour Control Layer." This term better encompasses the full range of materials available, allowing for precise selection based on the specific needs of a project. Standards like DIN 4108-3, ASHRAE 160, and AS/NZS 4200.1:2017 provide clear guidelines that classify membranes based on their ability to resist or allow vapour diffusion. Instead of using the generic term "vapour barrier," we should be talking about categories like high vapour permeability, moderate permeability, low permeability, and true vapour barriers. Each classification serves a specific purpose, and understanding these distinctions is crucial to ensuring the longevity and performance of a building envelope.

The DIN standard differentiates vapour resistance from an sd-value of 10 meters and upwards, whereas in Oceania, everything above this threshold is typically classified as a vapour barrier. This broad classification does not provide the level of detail needed for effective moisture control and can lead to material misapplication.

Here's a handy table that shows how the different standards compare:

Classification of Vapour Control Layers to DIN4108,ASHRAE160 and As/NZS4200.01:2007

When we choose the right vapour control layer, the outcomes are clear: improved building durability, enhanced energy efficiency, and healthier indoor environments. You can avoid the stress and financial strain that comes with moisture-related failures and instead feel confident knowing your project is designed to withstand the test of time. Correct terminology and informed material selection empower professionals to create sustainable and resilient buildings.

That way, you can stop feeling frustrated by recurring moisture problems and instead feel assured that your building envelope is performing exactly as it should. Because, at the end of the day, that’s what you want, isn’t it?

We'd love to hear your thoughts on this. Have you encountered challenges with vapour control in your projects? How do you approach material selection? Join the discussion and let’s push the industry toward better, more precise practices.